The best craftsmen are those who concentrate on their craft ? and nothing else. At Waffel Löser, we took this principle to heart from the very beginning and have focused solely on our speciality. Which is why we are so good at what we do: baking delicious wafers and designing and building the equipment required for the job.

We have chosen to pursue this path and have done so consistently. We have regarded the challenges faced on the way as both part of an ongoing development process and the sum of the experience already gained. There is no better and more natural foundation on which to build expertise and know-how. With an uncompromising commitment to the very highest quality and a keen ear for the needs of the market and our customers, we have constantly expanded our range of capabilities and strengths.

Our market leadership demonstrates that our chosen path has been the right one. Find out for yourself what we are capable of on the pages that follow. Form your own impression of Waffel Löser. A very warm welcome to you!

Daniel Schenk

CEO Waffel Löser

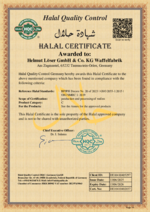

Being in the food industry, we are not only aware of all the regulations and standards, we also know what it takes to be able to communicate our products as top class on an ongoing basis. We communicate actively and listen carefully. This is why we are aware of the wishes and needs of our customers down to the last detail. With a sophisticated quality assurance system we ensure that there is no reason for complaint - from the raw materials right through to delivery.

When it comes to quality we leave nothing to chance and we always play it safe. This is why there is always a dough making facility coupled with every baking machine in the production process. In combination with fully automatic pre-mix production, this guarantees that we always keep a handle on things - even given our enormous variety of products.

In fact keeping a handle of things is a key issue when it comes to quality assurance measures as far as we are concerned. A high-performance, well-conceived and water-tight process control system has to contain essential back-up elements such as supplier registrations, rights and access controls and the final quality control by our food technicians, thus providing a self-contained and impenetrable quality assurance cycle. This reduces any potential error sources to an absolute minimum. And if the worst does come to the worst in spite of this elaborate system of back-ups, seamless documentation allows for precise batch tracing.

energy managment system

The Helmut Löser GmbH & Co. KG has committed itself to an efficient and lasting contact with energy and of course restricted resources. Aim is to reduce our energy consumption continuously. To achieve this aim, we hold an energy management system after German Institute for Standardization EN ISO 50001 upright.

SA 8000 Certificate

Baking the wafer is one thing, but for most of our customers the real work does not start until the Löser product has arrived on site in perfect condition. In order to guarantee that this happens we have developed a sophisticated warehouse and logistics system which ensures not only a smooth workflow but also the greatest possible adherence to delivery dates.

Space galore: our high-rise rack warehouse can hold an awful lot, with room for 10,000 pallets at peak times. As the last stage of our closed Löser quality chain, a computer-controlled warehouse management system goes into action before our wafers are finally delivered to the customer..

Delivery reliability

In our industry, reliability is of outstanding importance. For example, delivery reliability is a competitive factor when it comes to seasonal products. At the customer's request we organise pre-production so that minimum shelf life and residual production time match perfectly.

Automated stock removal and smooth logistical operations ensure that every pallet arrives punctually at precisely the place it is needed.